Running Tool: Pressure Activation

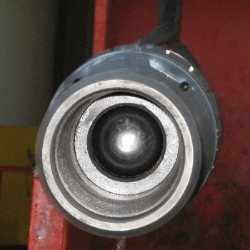

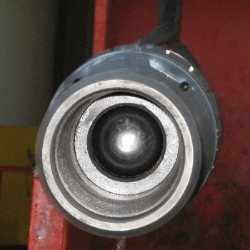

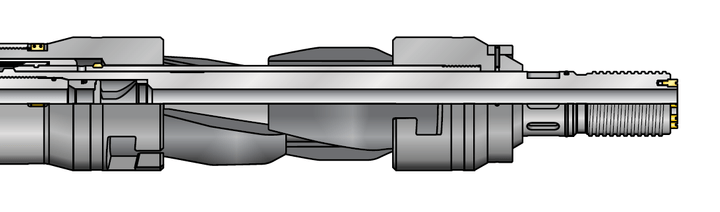

For phase one, I was involved in the functional testing of the running tool. The running tool was initially assembled and pressure tested to ensure all the seals were designed properly. As we completed the test, we made small modifications / updates to both individual components and the procedures that would facility future field use.

Running Tool: Torque Capacity

For phase two, I helped test the torque mechanism of the running tool to ensure the system was working as designed. We applied various torques up to 34,000 ft.-lbs. Additionally, I helped test the collet to ensure that it was able to hold high loads. I also tested the collet under pressure to verify it would release as expected at 7,500 psi.

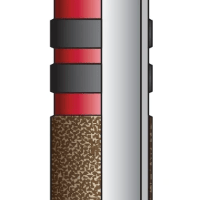

Tool Assembly / Verification

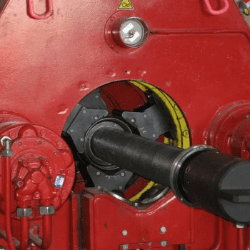

I helped put together the assembly and tested components to ensure proper fit and function in the shop prior to lab / field testing.

Lab & Rig Testing

I worked with other engineers to preform small lab tests to check tool functionality. I also processed data after the test to verify system functionality.

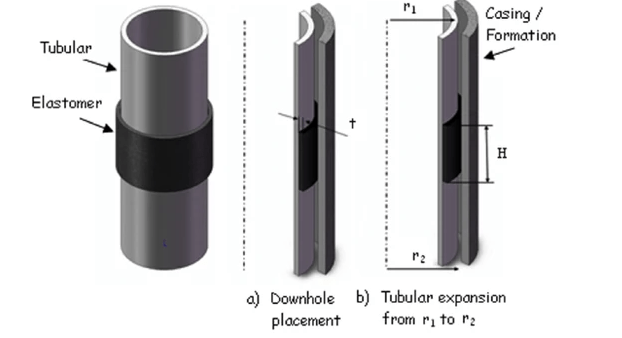

Fixture Design & Manufacturing Audit

I worked on developing testing fixtures. I dealt with vendor issues regarding molds and internal specifications.

Lab Testing & Design Improvement

I tested and investigated reasons for field failure. I examined the current manufacturing practices of our vendors and researched different options to develop an improved seal with increased realability.

Velocity Valve

Design & Development

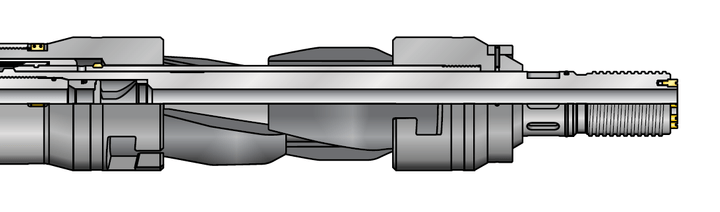

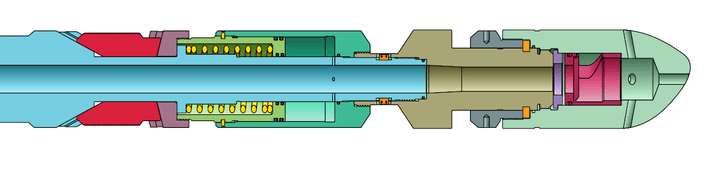

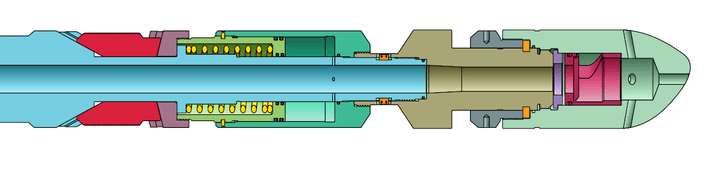

I developed a velocity valve as a means of actuating one of the tools . The valve would work by creating a high pressure differential as the flow rate was increased, which would shear screws.

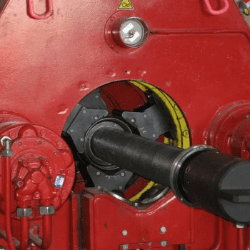

Lab & Rig Testing

I completed the initial testing of the tool in a hydraulic press. This ensured that the sub-assembly would move as expected. I compared the calculated screw shear values to lab results and adopted appropriate “fudge” factors . I then tested the tool in the rig, using a high flow rate pump.